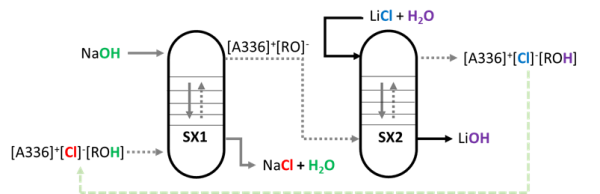

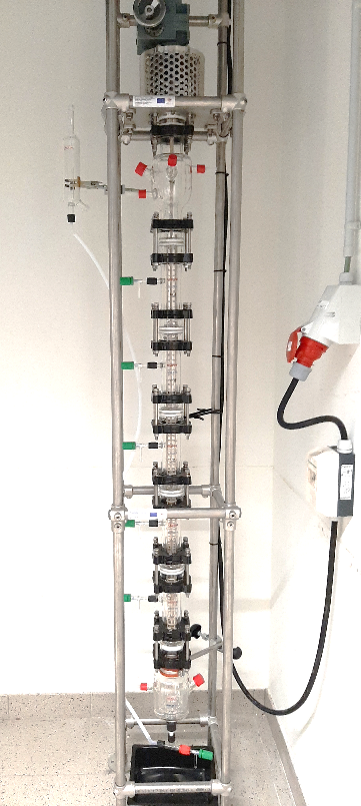

The ACROBAT project has made it possible that researchers of SOLVOMET, a research and innovation center for circular hydrometallurgy that is a member of the SIM² (KU Leuven institute for sustainable metals and minerals), have developed a two-step solvent extraction process that converts battery-grade lithium chloride into lithium hydroxide. The battery-grade lithium chloride was obtained by optimizing a hydrometallurgical flowsheet starting from spent lithium-batteries (LIBs) of the lithium iron phosphate (LFP) cathode type. These spent LFP LIBs were successfully provided by ACCUREC as industrial partner of the ACROBAT project. 75 L of 1.6 mol L-1 battery-grade lithium chloride was processed through an agitated Kühni extraction column with five column heights. A maximum conversion yield of 96% was obtained, resulting in a final lithium hydroxide product with more than 99.95% purity. These studies made the process of SOLVOMET ready to be further exploited on other industrial sources of lithium chloride, like for example brines.

Full reference paper:

Peeters, N., Riaño, S. & Binnemans, K. Conversion of Lithium Chloride into Lithium Hydroxide Using a Two-Step Solvent Extraction Process in an Agitated Kühni Column. J. Sustain. Metall. (2024). https://doi.org/10.1007/s40831-024-00815-4